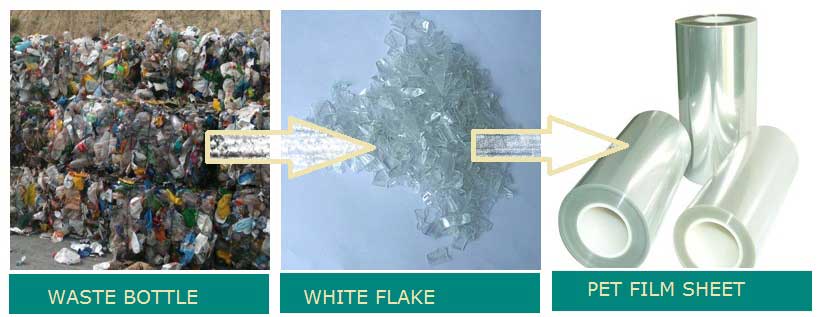

Demand for PET intended for film and sheet production is currently very high and still growing. This application is becoming increasingly important all over the world as it can assure high economic returns on the investiment, similarly to Bottle-to-Bottle and thermoforms applications.

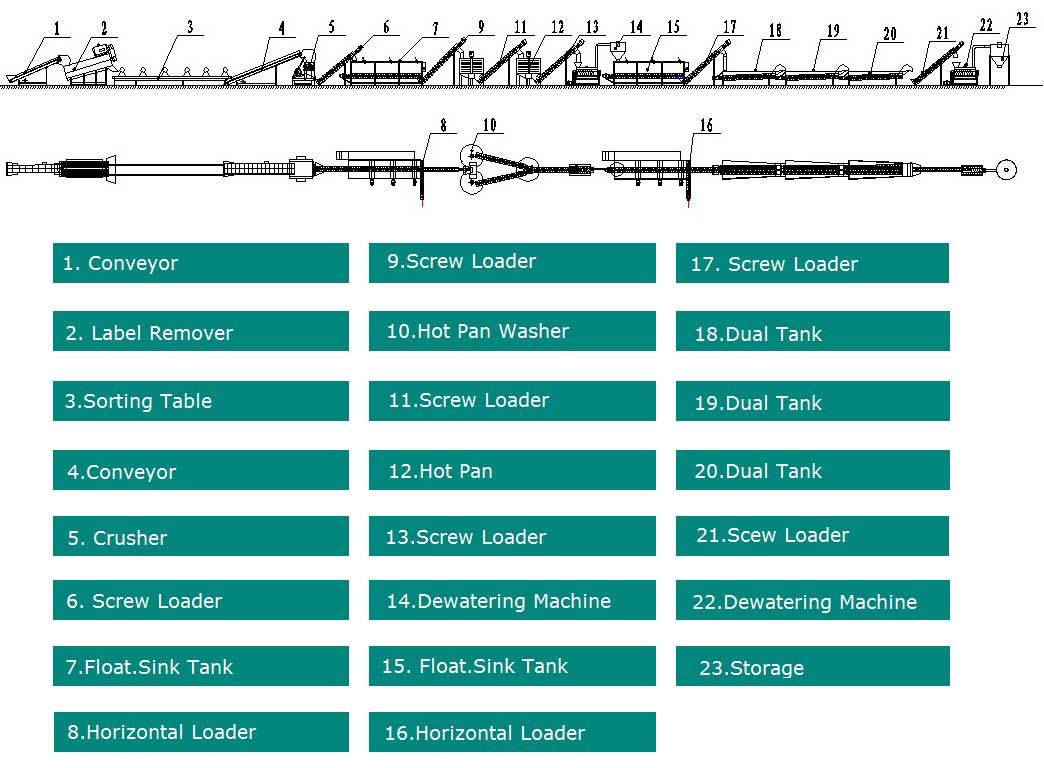

The PET recycling must be correctly designed and properly studied in order to obtain the highest amount of PET flakes matching the strict requirements of the downstream film equipments. Silver Python’s long experience in washing line and process PET bottles are a guarentee of its ability of meeting such demands. Our label remover and washer are capable of removing great amounts of contaminants. Centrifugal spin drying takes care of the removal of excess water.