PET washing line is also called PET flakes recycling, PET bottle recycling line, PET bottle washing line, PET recycling plant.

PET plastic bottle washing recycling production line equipment is mainly used to deal with daily life, discarded mineral water bottles, drink bottles, Coke bottles, PET plastic bottle or bottles crushed regeneration recycling.

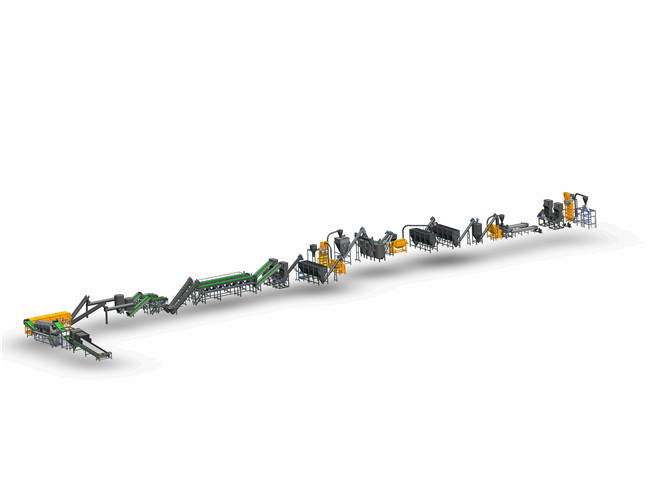

Its capacity is from 500kg/h-7000kg/h.

Machine material is made from stainless steel 304 or Carbon steel.

It has cold washing(500kg/h) and hot washing(more than 1000kg/h)

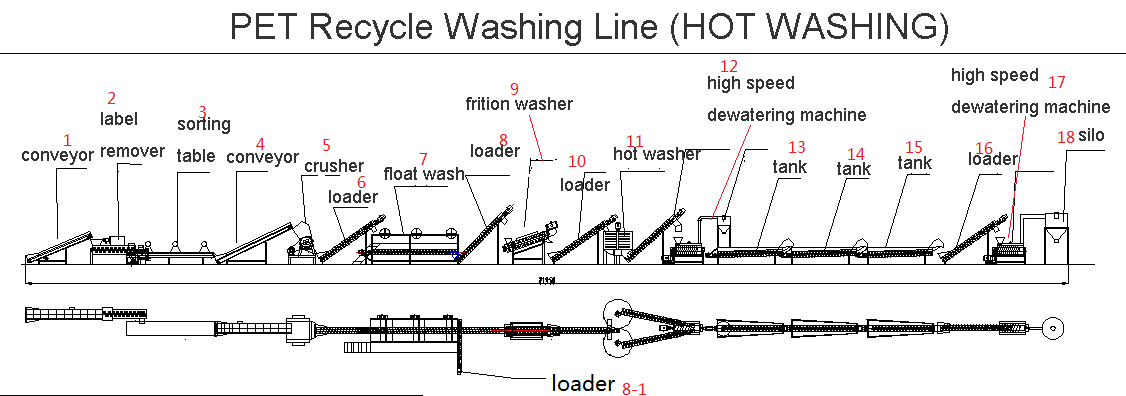

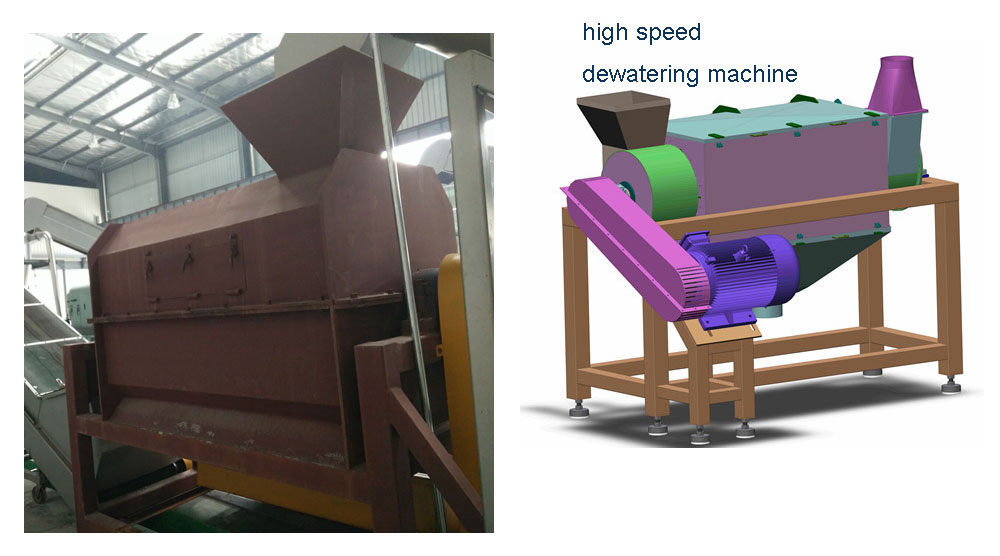

Its main process is conveyor to label remover(removing label) to sorting table(sorting) to conveyor (deliver) to crusher(crushing) to screw loader(deliver) to floating wash (washing)- to loader(deliver) to friction washer(friction) to screw loader(deliver) to hot washer(hot washing) to screw loader(deliver) to high speed dewatering machine(dehydration) to three washer tanks(washing) to screw loader(deliver) to high speed dewatering machine(dehydration) finally to silo(storing and packing)

PET bottles recycling becomes an economic opportunity even when the raw material prices are low. with more than 20 years of experience in PET recycling worldwide, Silver Python provided that the recycling plant is carefully designed with aim to minimize the operation costs and obtain first-quality PET flakes.

From the long experience gained in manufacturing of a large number of recycling lines, and detailed user feedbacks for all kinds of PET bottles recycling, Silver Python improved the PET recycling solutions continually, granting to the customers both output capacity and flakes quality and low operation costs of the recycling line.

The flakes produced are suitable for the following applications:

Bottle to Bottle

Bottle to Packaging

Bottle to Fibers

Bottle to Sheet

Bottle to Strapping

Standard output: 1000, 2000, 3000, 4000,5000 kg/h,7000kg/h

PET plastic bottle washing recycling production line equipment is mainly used to deal with daily life, discarded mineral water bottles, drink bottles, Coke bottles, PET plastic bottle or bottles crushed regeneration recycling.

Its capacity is from 500kg/h-7000kg/h.

Machine material is made from stainless steel 304 or Carbon steel.

It has cold washing(500kg/h) and hot washing(more than 1000kg/h)

Its main process is conveyor to label remover(removing label) to sorting table(sorting) to conveyor (deliver) to crusher(crushing) to screw loader(deliver) to floating wash (washing)- to loader(deliver) to friction washer(friction) to screw loader(deliver) to hot washer(hot washing) to screw loader(deliver) to high speed dewatering machine(dehydration) to three washer tanks(washing) to screw loader(deliver) to high speed dewatering machine(dehydration) finally to silo(storing and packing)

PET bottles recycling becomes an economic opportunity even when the raw material prices are low. with more than 20 years of experience in PET recycling worldwide, Silver Python provided that the recycling plant is carefully designed with aim to minimize the operation costs and obtain first-quality PET flakes.

From the long experience gained in manufacturing of a large number of recycling lines, and detailed user feedbacks for all kinds of PET bottles recycling, Silver Python improved the PET recycling solutions continually, granting to the customers both output capacity and flakes quality and low operation costs of the recycling line.

The flakes produced are suitable for the following applications:

Bottle to Bottle

Bottle to Packaging

Bottle to Fibers

Bottle to Sheet

Bottle to Strapping

Standard output: 1000, 2000, 3000, 4000,5000 kg/h,7000kg/h