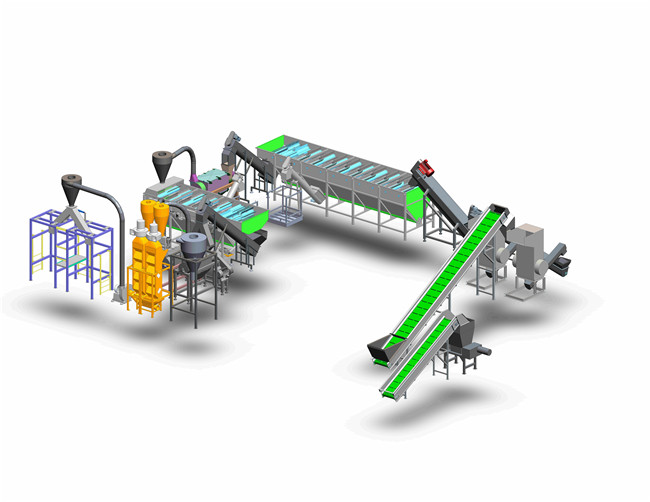

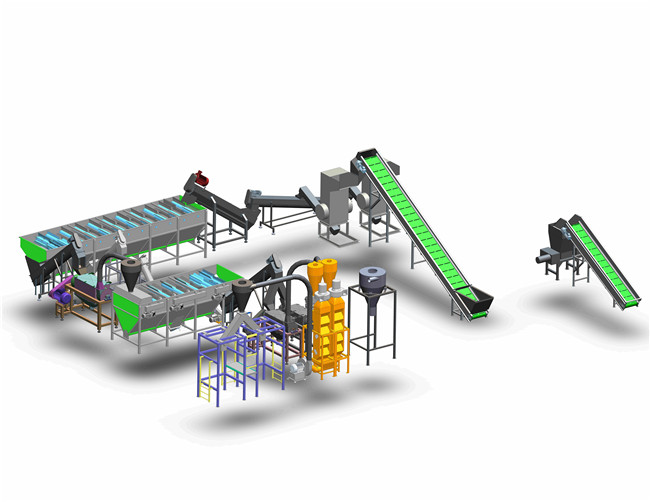

Regeneration recycle this set of equipment production line mainly deal with this set of everyday life milk bottle waste, cosmetic bottles, shampoo bottles, blue barrels, waste box, plastic chairs, plastic barrels HDPE, PP, PO, etc. floating rigid plastic cleaning.Its capacity is from 1000kg/h-7000kg/h.

Machine material is made from stainless steel 304 or Carbon steel.

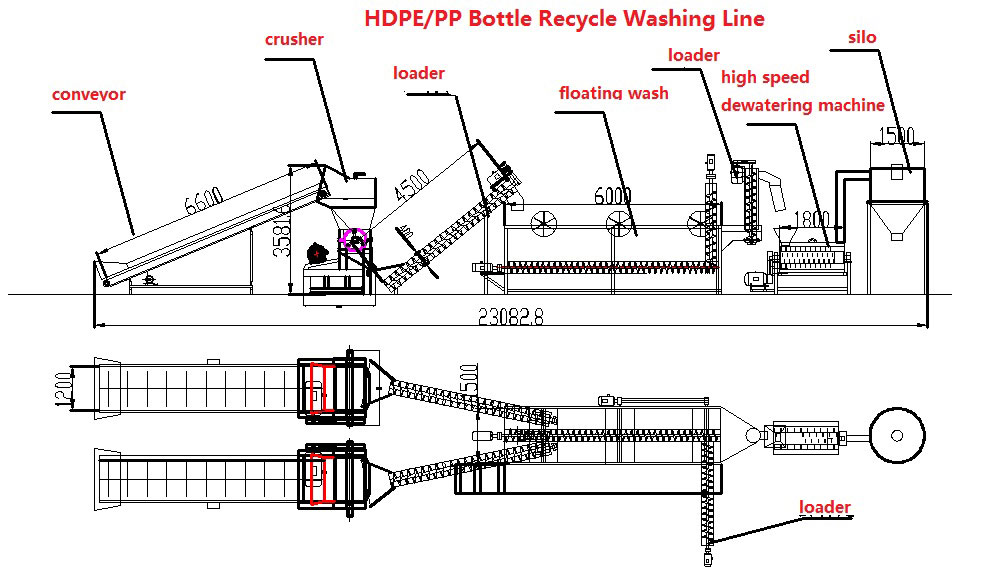

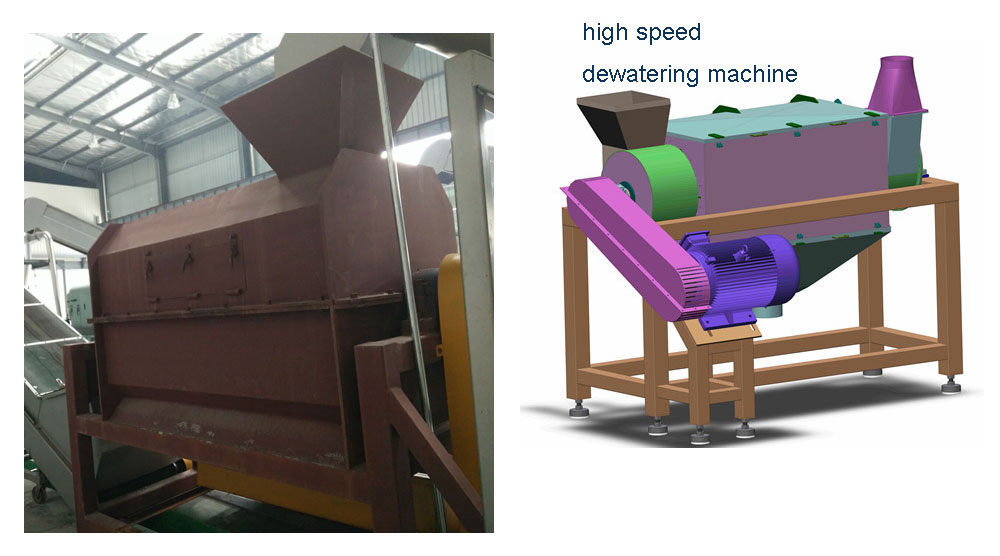

Its main process is conveyor to crusher(crushing) to screw loader(deliver) to floating wash (washing)- to loader(deliver) to high speed dewatering machine(dehydration) to dryer system(drying) finally to silo(storing and packing).

In the field of the recycling plants for HDPE and PP materials coming from urban and industrial collection sites, the HDPE and PP waste vary significantly from country to country, but also within the same country. Also the HDPE and PP materials has different size from small to big:

HDPE /PP bottles and containers,

HDPE /PP barrels and boxes

HDPE /PP chairs,desk, pipes

Silver Python has developed HDPE recycling line continuously, a series of modular components can be provided to match the different features of HDPE/PP materials.

With Silver Python’s tailor made recycling solutions, the most of the worst contaminants are eliminated in early step to reach the best final flakes quality with low consumption.

Capacity: 1000kg/h, 2000kg/h, 3000kg, 7000kg/h