Regarding HDPE bottle recycling, one of the main application is surely blow molding application, as complete line to recycle bottle crates of PE/PP became for the investors one of the most important final applications in terms of investment returns and of positive results.

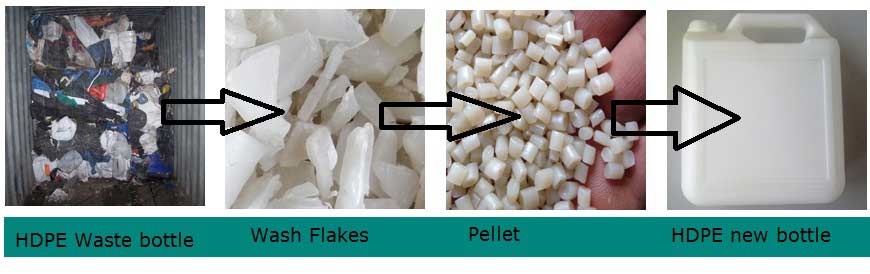

The process adopted by Silver Python in HDPE recycling for Bottle-to-Bottle applications is very similar to the one adopted for PET, consisting in sorting prewashing,wet crushing, hot washing, separation, centrifugation and drying. In the case of HDPE, flakes are then sent to an extrusion line.

During all these years of experience in plastic recycling process, Silver Python developed a precise and recognized know-how in the production of high quality HDPE flakes and can offer to its customers the adequate state-of-the-art recycling technologies to reach the correct parameters for HDPE -Bottle production.

HDPE, often referred to as plastic number 2, is extensively used in the production of bottles because of its low cost, accompanied by its high impermeability to liquids and good resistance, which makes it an adequate container for liquids. Some of its most common applications are milk and food containers, detergent bottles, body care as shampoo bottles, and motor oil bottles. HDPE is also used for PET bottle caps. The wide variety of uses and of substances that can be contained in HDPE is a demonstration of the remarkable chemical and physical characteristics it possesses. It is also an indication of the significant opportunities that can derive from PE/PP complete wash line.